I was having a small problem with my sewing machine. When I would press the button to cut the thread more often than not the thread would be cut so close to the needle that when I went to sew again the needle would become unthreaded.

|

| My sewing machine is an Elna X680. |

Clearly this was a tension issue, so I brought my machine to the sewing machine spa, in my case, Bittersweet Fabric Shop in Boscawen NH.

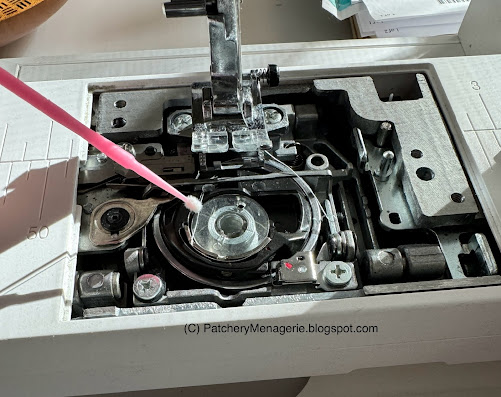

Randy knew just what to do (duh), and then he went into the innards of my machine to see if anything else was amiss. I asked if I could watch. Glad I did, because I learned a few things.

We all know dust can be an enemy. I use a little tool like this to get the dust out of places (particularly where the bobbin lives), and I had been told never to use compressed air to blow the dust out. Randy corrected me.He said I could VACUUM dust out of the area above, and then it was fine if I wanted to use a can of compressed air to blow the leftover bits out, because after that there wouldn't be many and they would be tiny.

HOWEVER,

WHY?

Apparently there can be little springs and other very delicate gizmos lurking under there that we cannot see and a pipe cleaner or tool like the one I used to use can dislodge said spring and cause the machine to run, shall we say, less than optimally. Randy found the little spring my overeager cleaning had dislodged and put it back where it belonged. (Consider me chastised.)

One hint he DID have was to use a pin to separate things in the bobbin race (where the bobbin lives) to get the dust that might get between those thin metal strips (I think it's kind of a spring). You can just blow the dust out with a puff of breath. (You know, your own lung power.)

We both agreed that sewing machine manuals do a poor job of explaining what we SHOULD do and what we shouldn't do.

It should also be noted that the thread I was using was partly responsible. A 60w thread, (such as the Precensia 60w thread I use) requires a different tension than a 50w thread. For my machine the AUTO setting was fine for 50w, but I had to reduce it to a 3 for my 60w thread. (On my machine AUTO = 4.)

Here's a big THANK YOU to Randy and Holly from Bittersweet Fabrics for letting me watch him work and allowing me to ask my questions and help us all out. Naturally, my machine now works like a charm and the thread cutter works precisely the way I want.

~ ~ ~ ~ ~

In other much more fun news, I ordered some postage stamps online the last time I had to ship a package via USPS. They arrived yesterday and I am delighted to share them with you. I think it is quite possibly THE COOLEST STAMP EVER.

I do not know if these beauties are available at your local post office, but you can get them at USPS.com.

5 comments:

I have always used a small paint brush to clean my machine. I thought those little swab things were cute and was thinking about getting some. Guess not. I will stick with my cheap paint brush that I stole out of one of my kids old watercolor sets. They never missed it.

This post is a keeper. Thank you for sharing!

Great tips! Love that your machine model is called eXcellence. Your quilts you create sure are.

Pass my thanks on to Randy for the cleaning tips!

I too heard the "never use compressed air" thing. I normally use a soft natural hair artists paint brush to clean the machine. The brushes that come with machines seem to have quite stiff coarse bristles that simply shove the lint around. A bit of folded pipe cleaner works well too.

I have not see those stamps, but then again, I stocked up right before they raised prices this summer, so haven't been in the PO office lately.

Oh, I'm guilty! Oops. And, yes, that's a great stamp!!

Post a Comment